Hello everyone. Had some spare time in my new married life and wanted to touch base with this great community!!

I have been emailing my customer base about needles and thread and how my experience may help those that are either new, or, just have never given these two important tools much thought. So, please read and enjoy this post and let me know your thoughts.

If you would like to catch up on past emails that I send to my 1800+ registered users of our digitizing service, you can follow me on Twitter (www.twitter.com) as Rick Macali (www.twitter.com/RMacali)

Needle size

Todays high-speed embroidery machines are asked to do quite a few different tasks than they were just 15 years ago. As a digitizing firm, In House Digitizing sees its fair share of our customers creativity. Having the luxury of working with one of the top retailers in the country, and now they have expanded to Europe, they have made us change the way we look at things .. we have turned the uncommon into common. The majority of our customers are contract and retail embroiderers. Their shop ranges are from one head to over 200 heads. These customers usually look for the common embroidery techniques used to create stunning corporate logos and decorative embroidery.

Proper thread usage

After the needle email that went out last week, I had more than 20 replies asking about the best thread to use. I will let everyone know that we use Madeira Classic Rayon 40, but, that doesn't mean that is the best choice for everyone; it is the best choice for us. As a digitizer, and a long time machine-operator, the thread that is used can make or break your design, and sometimes your day.

Generally, I'm sure that all 'good' sewing threads have a good sewability and have aesthetic appeal. I'm not going to detail a z-twist versus an s-twist thread, you can research that yourself, but, commercial and home embroidery machines use Z-TWIST threads. I hear many stories about production facilities that get great deals on thread from overseas factories, get it in and it won't sew for anything .. the thread is usually old, or more common s-twist thread.

The two common embroidery thread types are RAYON and POLYESTER, and they usually come in weights of 30#, 40# and 60#. The higher number, the finer the thread.

What to watch for in your thread choice

Elongation: All thread has a stretch to it before it breaks; polyester will stretch more than rayon, which has little stretch to it. The longer a thread stretches, the more chance you have looping on your embroidery.

Reliability: Some threads are made better than others. Some threads can be thinner in spots making the thread weaker in that area. Also, depending on the brand you use, it can have an abnormal amount of knots in the cone that can hinder productivity. It's not just that the knot can't make it's way through the needle's eye, but, thread coming off the cone can catch on the knot still in the cone.

Strength: Its breakability can be measured in your embroidery production. Continuous filament thread like polyester and rayon have a greater tenacity, or strength.

Proper twist: There is a definitive twist to the 2-ply embroidery thread. A thread with too much or too little twists can cause many problems with your embroidery. Commercial embroidery machines, by their nature, will ADD twists to thread during sewing. This will add twists to a z-twist thread and actually untwist an s-twist thread.

Common Thread Type Comparison

RAYON

Brilliant color

More colors

Runs smooth

POLYESTER

Stronger

Colorfast - harsh washing

Less expensive

Z-twist versus S-twist

Thread breaks

Wrong thread for job

Wrong or damaged needle

Thread defects

Bruised cones (dropped)

Excessive elongation

Too much tension

Worn machine parts

- thread path disks

- take up lever

- all guides

- burr on hook

- needle plate

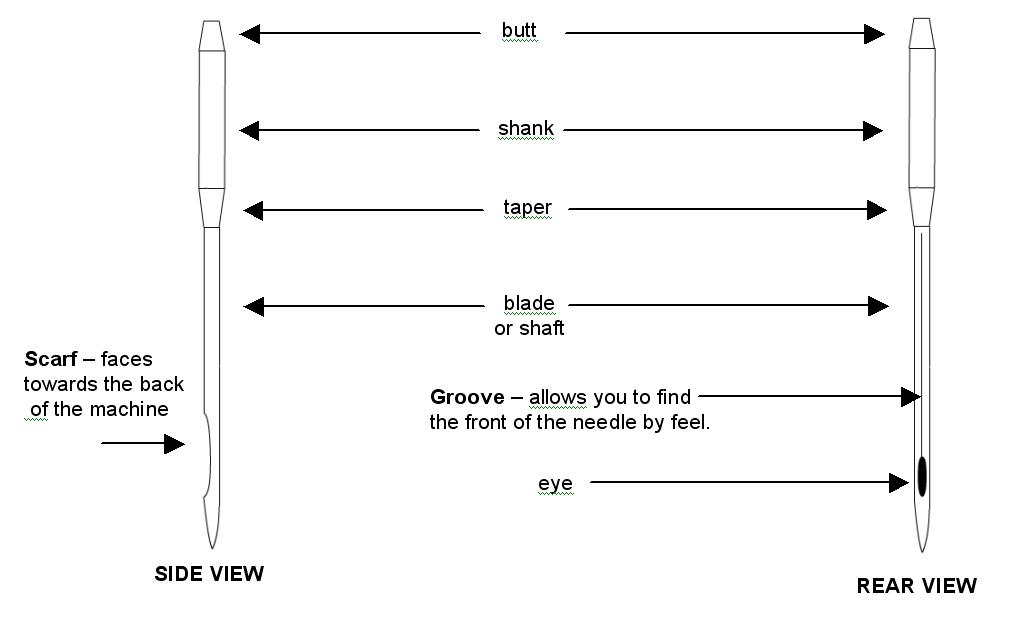

Needle parts

Notice the NEEDLE POINT starts at the top of the needle's eye. A light weight ball point is the best needle to use for knits. Stay away from sharp points on knits as you can cut the knit your are embroidering. Also, if you find you are cutting alot of knit material while you are embroidering, start by replacing your needle(s). Probably the MOST common cause of this is a burr somewhere on the needles point; many times, undetectable by sight or even touch.

Best regards,

Rick Macali

In House Digitizing

407-509-2400

https://www.inhousedigitizing.com