What do you do with a bobbin’s worth of thread wound on your

bobbin winding shaft? An old saying recommends making lemonade from lemons.

Here’s how I salvaged a major thread malfunction.

One of the first rules of machine embroidery is to not walk

away from the machine when it is running. Recently, while winding a bobbin, I

was glad I honored that rule. Either I had inadvertently started winding the

first bobbin thread behind the bobbin or the thread slipped while winding and

started wrapping around the bobbin winding shaft. By the time I noticed the

problem, a tremendous amount of thread had been expended.

Now what? I was stitching a freestanding applique (see a tutorial here), so the

bobbin was being wound from the spool with which I was stitching. It would be

bad enough to waste regular bobbin thread, but who wants to just throw out good

embroidery thread?

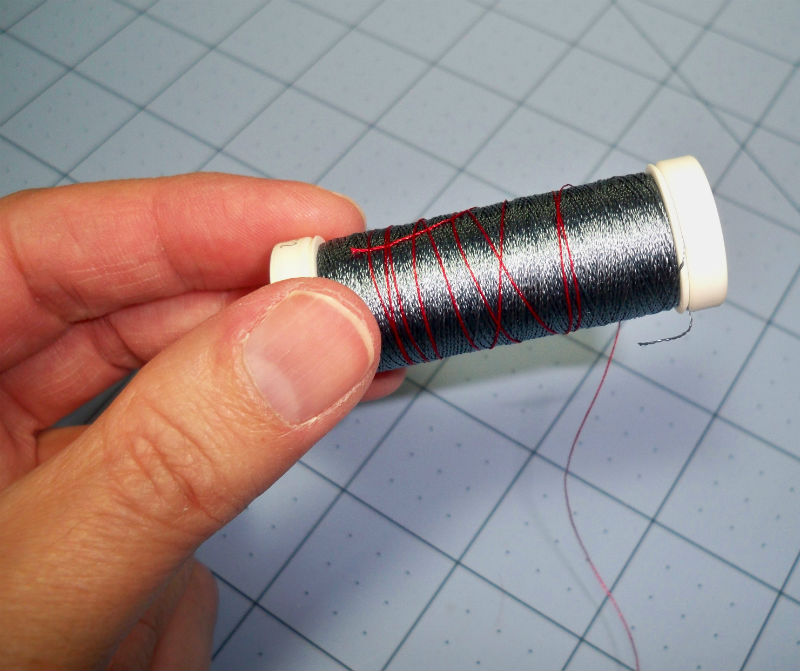

I decided to conduct an experiment to see how much of the mess

I could save. I didn’t have an empty spool (my four-legged helpers use them for

entertainment) so I took another spool of thread and carefully wrapped the excess

thread on to it.

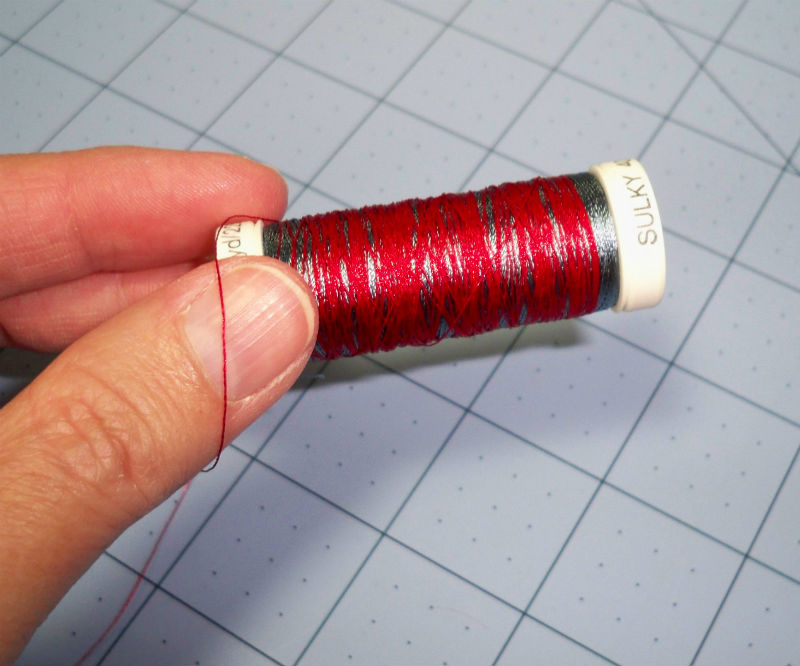

I chose a completely different color of thread on the spool

so I could easily see how much of the salvaged thread remained on it. I wound

the thread by hand and tried to evenly distribute it over the length of the

spool.

It worked great. I had enough thread to do all of the

placement and tack-down stitching as well as the red satin stitching on the

Santa hat.

Sometimes, mistakes teach us a lesson. I hope my mistake is

helpful to you some time!

Do you have any great “mistakes” to share?

Debbie SewBlest