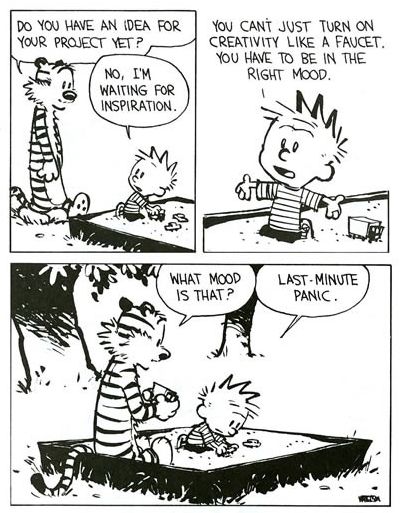

I love doing this blog and I love Calvin and Hobbs as

well:

Let's just say that they understand me very well!

Needles are the challenge that keeps on giving - over and

over. Let's think of the questions

possible:

·

Is it a bad needle right out of the package?

o

Closely inspect the needle under a magnifier and

good lighting.

o

Because the needle (most of them) has a flat

side, place just the needle (not including the shaft) on the edge of a flat

surface and roll it to see that it is straight and not damaged in any way.

·

Is it dull - how many stitches have I done?

o

Many machines have a 'counter' available. (When was the last time you went through your

manual to refresh your memory of where the counter is?) If you don't have a counter built in, you can

put an index card under the machine and put the date and an approximate number

of stitches - say 33K and keep adding. I

used to change my needle around 200,000 stitches.

o

Take into consideration the fabrics you are

using as well. If you are doing heavy

denim or vinyl? Those cut directly into

the number of stitches on a needle.

o

Be sure you are buying your needles in

bulk. At a 5 pack, they are

expensive. However, if you get 100, they

cost about the same as 3 - 5 packs of regular

needles. After about 15 of them, they

are FREE. Toss them!

o

Be sure to dispose of carefully, needles are not

nice sometimes. . .

·

Is it sticky, gummy or have a burr on it?

o

I clean a needle that is sticky with the:

§

Oil from my hair (run thumb and first finger

through your hair and on the needle.

§

Rubbing alcohol on a Q-Tip

§

Use a different adhesive, spray or self adhesive

stabilizer.

§

Toss the needle.

My time is limited, how about you?

·

Did it get bent somehow?

o

A bent needle is a major accident waiting to

happen. Remove it immediately

o

Bending can be caused by the thread being too

tight on the upper threading. I actually

have had a spool of thread (the ones with the slice on the bottom to hold the

thread) catch and hold the thread. It

does not even matter which way the slit was facing either.

o

There is no way to press the needle back into

service, bending it back will not correct the issue.

·

Why are the needle holes visible?

o

You are using too large a needle.

o

The needle has become dull.

o

Change your needle.

·

Is the thread path correct?

o

This is a personal favorite of mine! When your machine is working at 500 or 600

stitches per minute, it is bound to be in motion at least a little bit. I am always careful to put my thread in the

correct position, but it can and may jump just enough to make you crazy. Furthermore, you can look at it and not see

the culprit. If I am having needle

and/or thread issues, I suspect the pathway.

It only takes a few seconds, rethread.

If you are still having needle issues, check

out this blog

to refresh your memory about what embroidery is supposed to look like. In addition, I am sure you have had some sort of issue which I have not noted here. After all, if it can happen, it will. That blog includes such items as a tension test for the various formats as well. Testing tension should be part of your normal maintenance of your machine.

Using good tools such as needles and

quality thread is the best path to results that you will be very proud to show or

give. This special from Madeira is a value that anyone can use. Getting samples of quality stabilizer is the best part. Try before you buy. I have tried and do like Madeira thread above all others!

I really appreciate your reading my blog

and hope you find a few ideas and thoughts that help you along the way. To Teach is To Learn and I have learned so much for all of you, THANK YOU!

Best wishes to you and yours for a joyous and

safe holiday season.